We’re excited to release the updated version of our popular motor sizing software—free of charge (at least for now)—with regular updates and improvements already in the works. Sign up for our newsletter to stay informed—just the essentials, no marketing fluff (we promise).

We’re also looking to expand our motor database—so if you’re a manufacturer or rep, we’d love to hear from you! Get in touch to have your products featured and help us make VisualSizer Pro even more powerful for everyone.

This software package is made available as an aid to the selection of electrical motors, drives, and additional components. Copperhill Technologiesn does not guarantee the results and cannot accept the responsibility for their interpretation. Consult a qualified representative to confirm the final selection.

Thank you for trying out VisualSizer Pro. Please note the following:

⚠️ Demonstration Version

This release is intended for demonstration purposes only. While we’ve conducted extensive testing, some bugs may still exist. Your feedback is essential to help us optimize functionality and correct any remaining issues.

📦 Motor Database Status

The motor database currently included is not up to date. It contains data from a previous version of the software, last validated several years ago. We plan to update it frequently based on our own research and—most importantly—feedback from users like you.

You can also add, delete, or modify motor data directly using the built-in database editor.

📘 User Manual & Newsletter

We’re in the process of creating a comprehensive user manual, which will be made available on this website. If you’d like to receive update notifications, please sign up for our newsletter. We only use it to share relevant updates—no spam or marketing pitches.

💡 Support Policy

VisualSizer Pro is offered completely free of charge. While we welcome bug reports and suggestions for improvement, we are unable to provide individual technical support at this time. We appreciate your understanding and encourage you to reach out if you discover any issues or have ideas to improve the software.

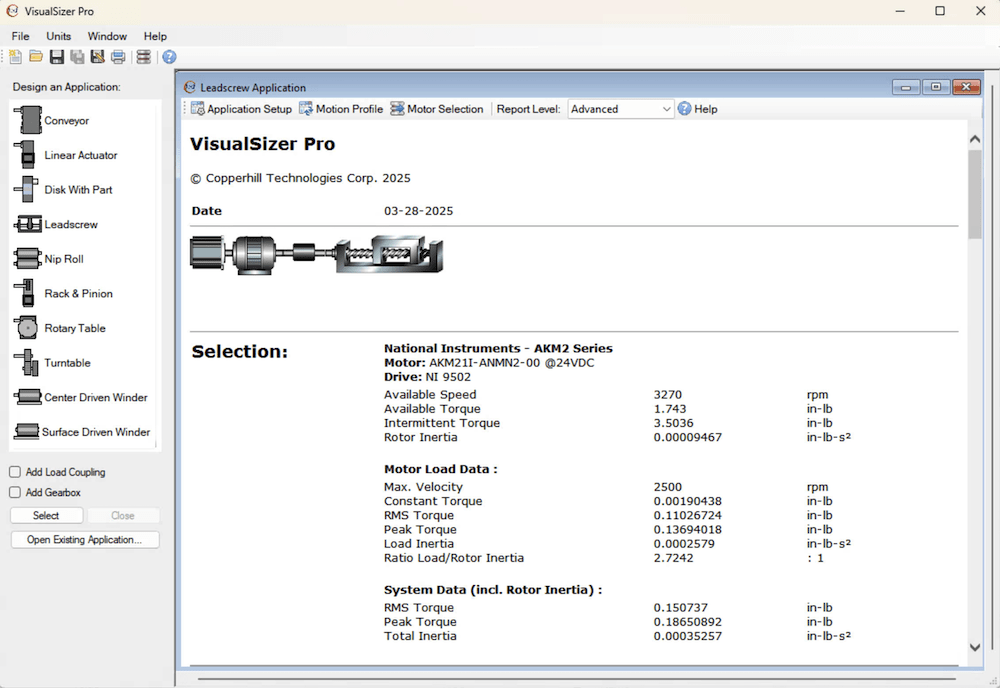

VisualSizer is a powerful, manufacturer-independent servo motor sizing and selection software for Windows. It simplifies the process of choosing the right motor and drive system by leveraging an extensive database of motor/drive/amplifier combinations from various manufacturers.

VisualSizer is a powerful, manufacturer-independent servo motor sizing and selection software for Windows. It simplifies the process of choosing the right motor and drive system by leveraging an extensive database of motor/drive/amplifier combinations from various manufacturers.

Key Features:

- Comprehensive Motor Database – Includes products from leading motion control manufacturers, with continuous data updates.

- Database Editing Tool – Allows users to add, delete, and modify motor data for customization.

- Trusted by Industry Leaders – Used and tested by reputable motor manufacturers, including GE Fanuc, Siemens Energy & Automation, Oriental Motors U.S.A., Schneider Electric, Baldor, Moog, Danfoss, and more.

- Rapid Motor Selection – Automates the time-consuming process of determining the optimal motor and drive based on application specifications.

- Advanced Motion System Design – Supports the integration of mechanical components like leadscrews, timing belts, and gearboxes.

- Smart Motor Matching – Calculates torque, speed, and inertia requirements, then provides a ranked list of suitable motors, allowing users to make informed decisions.

- Expert Guidance – Simplifies complex motion control engineering with an intuitive, knowledge-driven approach.

With VisualSizer, motion control engineers can achieve accurate and efficient motor selection in minutes, saving time and ensuring optimal performance. More information…

VisualSizer is Back!

After several years on hiatus, I’m thrilled to revive my all-time favorite project—the VisualSizer motor sizing software for Windows! It’s time to bring this powerful tool back to life, making it even better for engineers and motion control professionals.

Of course, there’s work to be done—updating the website, adding documentation, and ensuring everything runs smoothly. But the most important part? You! We need users and fresh motor data to make VisualSizer truly valuable again.

Originally, VisualSizer came with a database of over 6,000 servo and stepper motors, but much of this data is now outdated. That’s where you can help! If you’re interested in supporting this revival, please sign up for our newsletter—I’ll keep you updated on progress and share details on how to contribute motor data.

💡 Rest assured, your name and email will only be used for project updates—no marketing, just meaningful collaboration. Right now, the focus is on building connections and bringing VisualSizer back better than ever.

![]() Let’s make this happen together! 🚀

Let’s make this happen together! 🚀

Wilfried Voss

Creator of VisualSizer

Latest News

History of Robotics: From Ancient Automata to Modern AI-Driven Machines

Understanding Stepper Motors: A Technical Overview

Overview of AC and DC Electric Motor Types

Explore the Fascinating World of Robotics!

AI-Powered Robotics: Modern Approaches to Perception, Control, and Applications

AI in Motion Control Applications: Trends, Future, and Business Impact

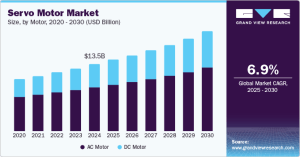

Servo Motor Market Analysis (2025–2030)

What is VisualSizer – An Overview

Reviving VisualSizer: Upgrading for the Future with a New C# Version

by Wilfried Voss

The importance of servo motor sizing should never be underestimated. Properly sizing a motor not only leads to substantial cost savings—reducing energy consumption, purchasing and operating expenses, and downtime—but also enables engineers to design more efficient and reliable motion control systems. However, in an era where modern technology emphasizes tuning and programming, fundamental knowledge of mechanical systems and their impact on motor speed, inertia, and torque requirements appears to be diminishing.

Servo motor sizing involves a series of mathematical equations, which, although well-documented, are often presented without direct relevance to the sizing process. This book focuses specifically on servo motor sizing, providing a detailed exploration of inertia and torque calculations for standard mechanical components, as well as a comprehensive guide to the motor selection process. More information…